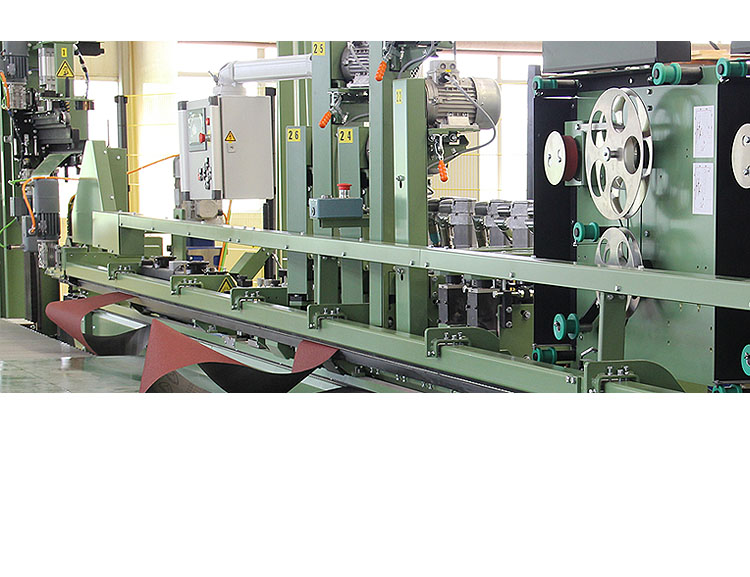

Accessories: Aggregates

Scuffing aggregates, gluing aggregates, drying stretches and tape applicator for preparing the joints when producing endless abrasive belts.

Aggregate type D/DU

- For skiving the grain with a diamond cup wheel.

The aggregate is working from the top (type D) or from the bottom (type DU). The diamond cup wheel is often used for overlap joints or when producing belts with a top skive. The aggregates can be adjusted precisely in all directions to ensure an optimal processing of each material.

Aggregate type C

- For grinding and scuffing with an abrasive belt parallel to the joint.

The aggregate type C is working from the top and it can be adjusted precisely in all directions to ensure an optimal processing of each material.

Aggregate type P/PU

- For pointing or scuffing with an abrasive belt, a wire brush or other tools.

The aggregates are working from the top (type P) or from the bottom (type PU). Both are typically used before gluing the belt ends. The aggregate works at an angle to the joint. The angle should correspond to the joint angle of the belt and can be adjusted. The aggregates can be adjusted precisely in all directions to ensure an optimal processing of each material.

General information

- All aggregates can be easily adjusted in height, forward/sideward inclination and angle.

- More than one aggregate of the same type is often used when working with large machines or double lap preparation machines. This possibly allows a preparation of both lap ends in the same working process or an easy conversion when changing the joint type.

- The aggregates can be easily integrated in the working process by pushing them forward or backward and this guarantees an efficient working. When using more than one aggregate of the same type, they can be set for repeating applications and do not need to be readjusted every time, which is an advantage when producing overlap and tape joints with the same machine.

Aggregate type G/GU

- The gluing aggregate works with a driven glue applicator roll and supporter roll which are hardened. The gluing aggregate type G is working from the top and type GU is working from the bottom. The cleaning parts are very easy to remove from the machine. The aggregate works with two different speeds. The quantity and the width of the glue are adjustable.

Aggregate type LS/LSU

- Glue spray head that allows various settings like spray pattern, inclinations, distances and glue quantity. The glue spray head type LS is working from the top and type LSU is working from the bottom. The glue will be kept in a pressure tank to ensure a significant increase of the processing time. The innovative and slowly rotating cover tape is used to apply an absolutely precise adhesive film.

- The cleaning process of a glue spray head is much easier and faster than for the glue applicator roll.

General information

- The aggregates can be easily integrated in the working process by pushing them forward or backward and this guarantees an efficient working.

Drying stretches type T/TU

- For drying the glued belt ends

(type T is working from the top, type TU is working from the bottom). - The intensity of the drying stretches can be adjusted by a power controller.

- The drying stretches are necessary to ensure an effective working with the tape applicator type FAS.

- The joining process for overlap joints will be accelerated due to the fact, that the lap ends are already pre-dried.

Tape applicator type FAS

- Continuously working tape applicator for the automatic application of tapes on joints when producing endless narrow belts and wide belts.

- Thanks to the tape applicator type FAS the tape will be automatically glued, dried, applied on both lap ends and finalized by a flush cut.

- The length of the tape to be applied is freely selectable (tapes up to 25 mm can be processed).

- When processing long belts, a tape is applied only on every second lap end.

- More than one aggregate of the same type are used when working with large machines or double lap preparation machines. This allows a preparation of both lap ends in the same working process.

- The aggregates can be easily integrated in the working process by pushing them forward or backward and this guarantees an efficient working.

- When using more than one aggregate of the same type, they can be set for repeating applications and do not need to be readjusted every time, which is an advantage when producing overlap and tape joints with the same machine.

How may we help you?

Contact us! Our experts will be happy to support you.

Tel. +41 52 720 70 30

info@amackerschmidag.com